THE BENEFITS OF STEAM ACCUMULATION

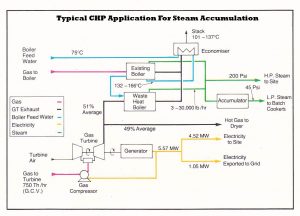

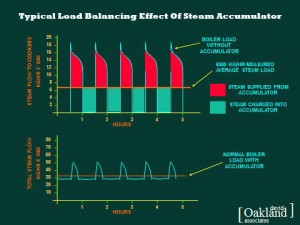

A steam accumulator can maximise your operational effectiveness. Just some of the practical advantages to be gained are instantaneous response to variable demands, constant process conditions and the ability to operate with smaller boilers. Bottom line benefits derive from reduced fuel consumption through boiler load stabilisation, coupled with enhanced product quality and improved productivity.

The theory of steam accumulation can be successfully applied to any steam dependent batch process. Its use therefore extends into all areas of manufacture – be it food, drink, chemicals, textiles, paper and board, EPS, pharmaceuticals, rubber etc., and all manner of what might be regarded as more specialised uses.

For most clients, the first stage is an application study for ‘steam storage’ including a review of boiler utilisation and steam distribution. Where appropriate, David Oakland Associates will study all aspects of your steam supply system, demand profiles and pipework design. Recommendations will then be made for the most cost effective, economic and operationally advantageous solution for implementing steam accumulation.